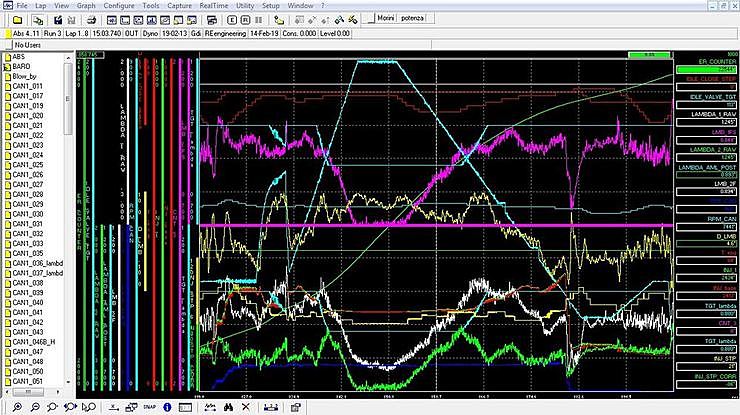

Data recording and processing; it is essential to know in detail the phenomenon, in order to be able to analyze it.

REengineering engine testing offers different acquisition systems, fixed and portable, interfaced with the main platforms paired with a wide range of sensors.

We have developed control systems suitable for different sectors:

- Engine homologation

- Vehicle diagnostics

- Vehicle calibration, tuning

- Control unit calibration and validation

OUR TEST BENCHES CONTROL SYSTEM:

- Brake PID management (rpm, torque, percentage) back-activated in 3 ms, with predictor

- PID temperature management (water, oil, intake air, environment)

- PID pressure management (also intake and exhaust)

- Communication management via double CAN bus (ECU, sensors, …)

- Execution of dynamic profiles for homologation cycles on chassis dynamometers

- Interfacing with supervision programs

- Autonomy in customizing applications (know-how safeguard)

- Scalable hardware/software configurations

- Budget enhanced by incremental steps

- Modularity for different applications

Developed on three levels: FPGA, Real Time, Windows.

- Telemetry of parallel loop times, with priorities

- “Down – up” hierarchy for input/output flows and controls

- Analog inputs managed individually

- Activation / timing / filter (digital, statistical)

- Digital inputs; analog and digital outputs

- Alarm status of the test room

- Brake and accelerator set (high dynamics)

- Valve control for fluids (low dynamics)

- Special analog inputs: high definition (24 bit) for load cell

- High definition (24 bit) for thermocouples / resistance thermometers

ADS – DOE Step – implementation of STRATEGIES

- Executes what is written in the Excel file

- Export to text file (Excel versions) – parameterization

- Self-learning of limits (grid)

- Memory of previous behaviors (uut) – reactions in case of boundaries violat./faults

- Soft and hard limitations

- and much more ..

Discover more about our engine test cells

REengineering Engine Testing:

- 20 years of experience in engine testing, close contact with the Automotive and Motorsport sectors

- In-depth knowledge of precision mechanics and power electronics

- Perfect knowledge of control PIDs and dynamics involved in motor testing

Contact us at info@re-eng.it