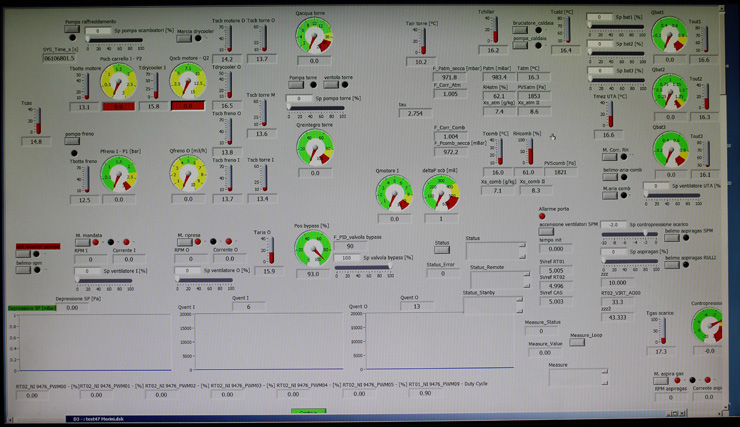

The utmost commitment of REengineering is focused on the application of the dyno room, where each setting is tailored to meet all customer’s needs. The main control system is entrusted to an extremely flexible platform, in continuous evolution, which allows to virtually implement any kind of application, in a very dynamic way.

We focus on the repeatability and accuracy of the measurement of our dynamometers; we have implemented automatic “real-time” control systems, in order to be able to carry out personalized cycles, with extreme accuracy.

We can configure the test cell at various levels, we have tools integrated in the system such as:

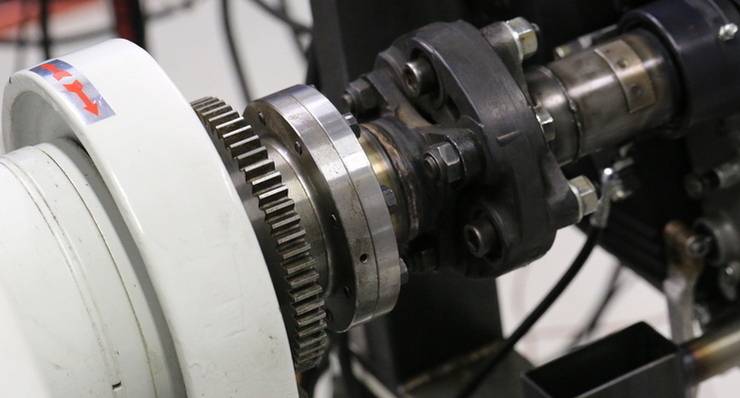

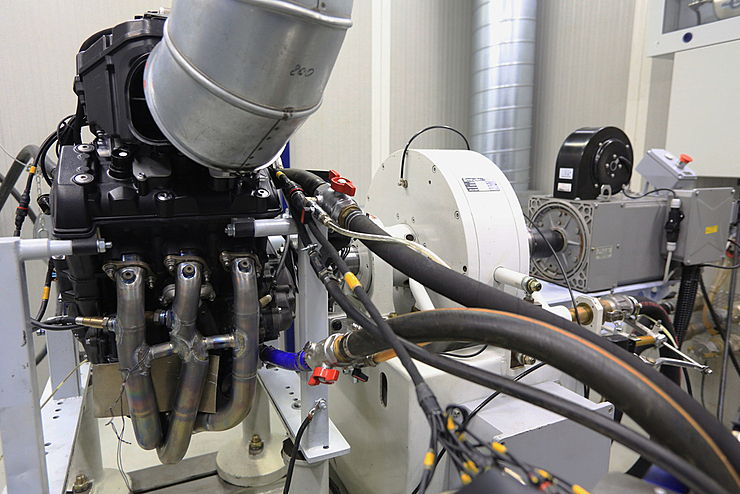

- “Tandem” configuration, with asynchronous motor coaxial to the brake axis and torque flange in axis. A new chapter in the field of engine calibration, which opens up the possibility of extremely accurate tuning of parameters such as minimum combustion throttle, engine brake, use simulation, homologation cycles etc. Torque / power measurement by means of a torque flan- ge and load cell, also in a redundant manner

- Blowby meter and instantaneous consumption meter

- Mechanical controlled actuators (throttle, clutch, gearbox …)

- Linear lambda probes (analogue and CAN), Thermocouples

- Layout configuration of exhaust systems adaptable to controlled depression

- Adjustable ventilation in flow rate and depression

- Data acquisition at high speed or for long duration cycles

- Deep CAN integration between test cell and system under test, real-time export of any acquired value (eg lambda, power, pressures, temperatures), directly to any CAN logger. This make post processing of very simple, offering the acquisition format usually used by the customer

- Combustion air conditioning, controlled in temperature and humidity with superheated steam generator, to constantly replicate the test conditions or reproduce extreme situations of use

- Fuel air conditioning, temperature-flow-pressure management

We certainly do not neglect the part concerning safety, both of the personnel and of the sy stems, in fact all the test phases are remotely supervised without any contact with the “hot” part through continuous recording cameras, and IG541 gas saturation fire protection system with automatic control and flame sensors in the cell, emergency shutdown systems, with mechanical stop, electrical and power cut.

Discover more on our acquisition system

REengineering Engine Testing:

- 20 years of experience in engine testing, in Automotive and Motorsport

- In-depth knowledge in the fields of precision mechanics and power electronics

- Perfect knowledge of control PIDs and dynamics involved in motor testing

- Partnerships with big players in the automotive business are continuously allowing us to develop a full range of services from prototype to homologation process

Contact us for more information